NEWS

| Title | LS Cable & System develops a cable for high-speed railways |

|---|---|

| Date | 2019-09-19 |

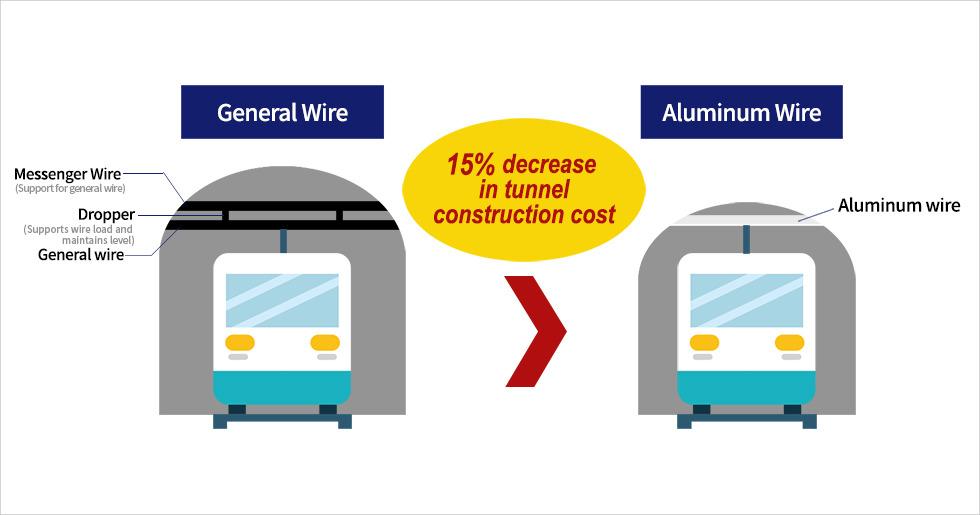

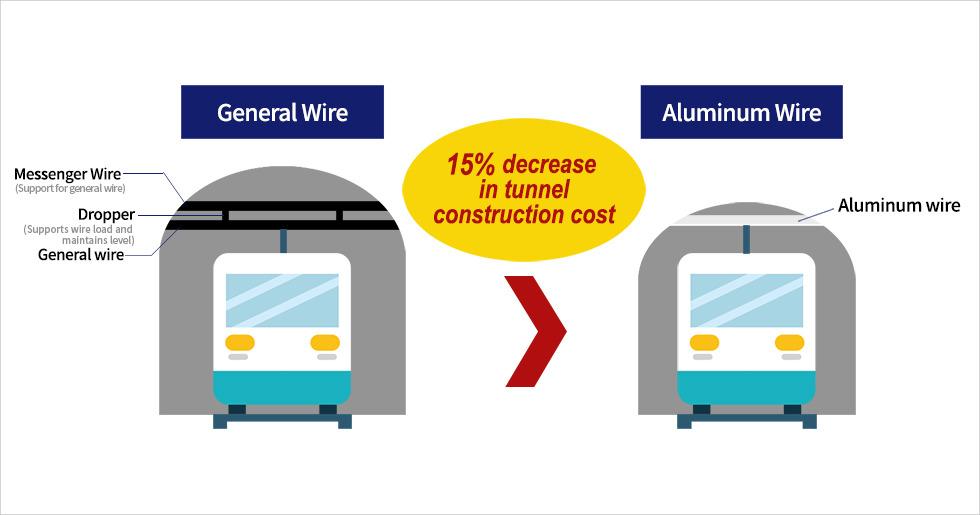

■ Reduces the tunnel construction cost by over 15%, eliminates the stoppage of train operation due to disconnection

■ Second in the world to develop, anticipating export substitution effects and expansion into global markets

On September 19, LS Cable & System (President & CEO Roe-hyun Myung) announced that it developed a ‘rigid bar’ for high-speed railways.

This is a system that supplies power in aluminum bar format, instead of copper trolley wires. There is no need for facilities to support the trolley wires, so the tunnel size can be dramatically reduced.

Using the rigid bar, the tunnel construction cost for high-speed railways such as the KTX or GTX, etc. can be reduced by more than 15%. In the case of GTX, over 99% passes an underground tunnel, so the cost reduction effect is even bigger.

Furthermore, a rigid bar does not cause accidents where the train stops due to disconnection, and there is almost no need for maintenance.

Following Switzerland, it is the second in the world to develop the rigid bar, so import substitution effects are anticipated. In the case of low-speed products for subways, LS C&S succeeded in localization in 2013. However, for ultra-high-speed products at 250km/h, Swiss products were used in the Bujeon-Masan double track line in 2018, and it depended entirely on imported products.

CTO (Chief Technology Officer) In-ho Lee of LS C& S said, “The global market for rigid bars is growing, with railroads are becoming high-speed and long-distance, and wide-range express trains like GTX increasing. Based on the local commercialization performance, we will be expanding aggressively into the global market.”

This system development was carried out as the Ministry of Land, Infrastructure, and Transportation’s national project since 2014. It is an excellent example of the private and public joint R&D, and the co-existence of large and small companies with the participation from Korea Railroad Research Institute, Korea Rail Network Authority, and railway equipment companies such as Pyungil and D2Engineering.

Doctor Gi-won Lee at Korea Railroad Research Institute said, “The high-speed of underground and tunnel sections is becoming a global topic. It is very meaningful that we developed a world-class high-speed bar with our local technology.”

■ Second in the world to develop, anticipating export substitution effects and expansion into global markets

On September 19, LS Cable & System (President & CEO Roe-hyun Myung) announced that it developed a ‘rigid bar’ for high-speed railways.

This is a system that supplies power in aluminum bar format, instead of copper trolley wires. There is no need for facilities to support the trolley wires, so the tunnel size can be dramatically reduced.

Using the rigid bar, the tunnel construction cost for high-speed railways such as the KTX or GTX, etc. can be reduced by more than 15%. In the case of GTX, over 99% passes an underground tunnel, so the cost reduction effect is even bigger.

Furthermore, a rigid bar does not cause accidents where the train stops due to disconnection, and there is almost no need for maintenance.

Following Switzerland, it is the second in the world to develop the rigid bar, so import substitution effects are anticipated. In the case of low-speed products for subways, LS C&S succeeded in localization in 2013. However, for ultra-high-speed products at 250km/h, Swiss products were used in the Bujeon-Masan double track line in 2018, and it depended entirely on imported products.

CTO (Chief Technology Officer) In-ho Lee of LS C& S said, “The global market for rigid bars is growing, with railroads are becoming high-speed and long-distance, and wide-range express trains like GTX increasing. Based on the local commercialization performance, we will be expanding aggressively into the global market.”

This system development was carried out as the Ministry of Land, Infrastructure, and Transportation’s national project since 2014. It is an excellent example of the private and public joint R&D, and the co-existence of large and small companies with the participation from Korea Railroad Research Institute, Korea Rail Network Authority, and railway equipment companies such as Pyungil and D2Engineering.

Doctor Gi-won Lee at Korea Railroad Research Institute said, “The high-speed of underground and tunnel sections is becoming a global topic. It is very meaningful that we developed a world-class high-speed bar with our local technology.”